The growing demand for production capacity at West European companies remains consistently high and is increasing at highly automated manufacturing companies. Betech especially sees the demand for large series production increasing as more companies choose to seek suppliers relatively close to their own locations. Initiating high-volume production and nearshoring production to the Netherlands from low-wage countries requires not only enormous production capacity but also the assurance and, to some extent, guarantee of a high level of quality that is demanded. It is an interaction that continues to increase capacity.

Netherlands’ Largest Mass Turning Company

To continue meeting this growing demand, Betech is constantly expanding its production capabilities and capacity. This year, the number of CNC lathes will increase to a total of 90, all fully automated and focused on 24/7 high-volume precision turning production. The continuous increase in capacity also requires more efficient processes in terms of quality management.

Data-Driven Quality Management

For several years now, all measuring instruments, both on the shop floor and in quality management, have been fully digitized. The quality of each order is already 100% driven by SPC data. This includes not only regular high-quality measuring tools but also advanced 3D measuring machines. The real-time transfer of measurement data between operator and measurement room minimizes errors and eliminates differences in measurements while capacity continues to increase.

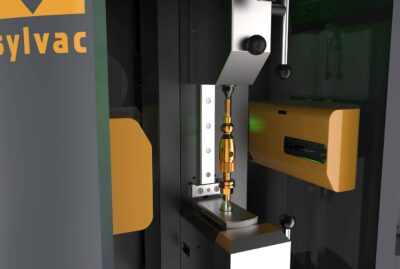

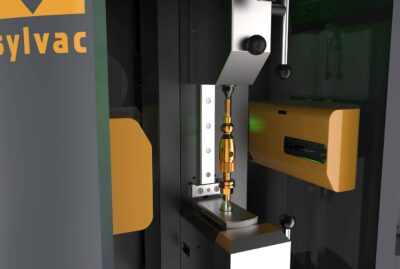

Automatic Measurement with Swiss Precision within 0.5 µm

Betech goes even further in the field of quality and automation with its most recent investment in Swiss precision measurement technology. Where a complete product measurement previously took an average of 15 minutes, the product is now automatically recognized, fully measured, and the data returned to the measurement technician and the CNC machine within 3 to 5 seconds. With a repeatability accuracy of less than 0.0005 mm, this approach is completely independent of human influences and provides direct control for the machine and operator to adjust the process if necessary to achieve a flawless result.

Our thanks also go to Andes Meettechniek for the excellent service in finding the right measuring machine.