Manual with tolerances per material

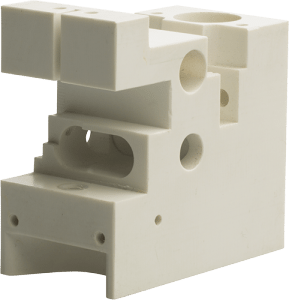

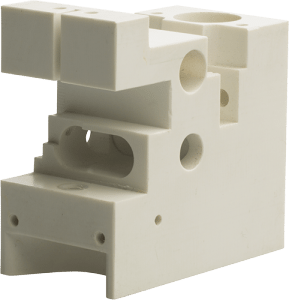

Plastics are often used to replace conventional materials in existing constructions. The material is lighter in weight, has excellent mechanical properties, is often cheaper and also very durable.

Engineers often choose plastic parts instead of steel, if the application and circumstances allow this. However, engineering with plastic is different than with steel. Plastics can be processed accurately on an Mµ, but it will not retain its shape due to viscoelastic properties and external influences. Mostly only the material type is changed on the production drawings and the requirements set for stainless steel, aluminum or brass products remain the same.

“Plastics can be processed accurately on an Mµ, but due to visco-elastic properties and external influences, it will despite tempering not keep its shape.”

Material-specific tolerances for machined plastics

Based on information from suppliers and experience in plastic machining, Betech provides a perfect manual for clearly researching the (im)possibilities in plastics.

This download provides insight into which tolerances can be guaranteed to what extent. Broken down by shape and material.

Download the manual by clicking HERE

Causes

Due to the use of modern CNC machines, the manufacturability is not decisive for achieving the tolerances for steel structures, but the conditions under which the plastic subsequently becomes exposed. Logically, this is especially the case with small dimensions, for example with a tolerance less than 0.1 mm. Such measures can, after detaching the workpiece from the machine table, change by various factors.

In particular thermal expansion, volume change due to moisture absorption, as well as shape change due to residual stresses in the material, are important factors causing closely tolerated sizes in certain plastics cannot be guaranteed after processing.

Do you have any questions about the possilbities or do you need help by engineering your product? Please feel free to contact us!