An investment in efficiency

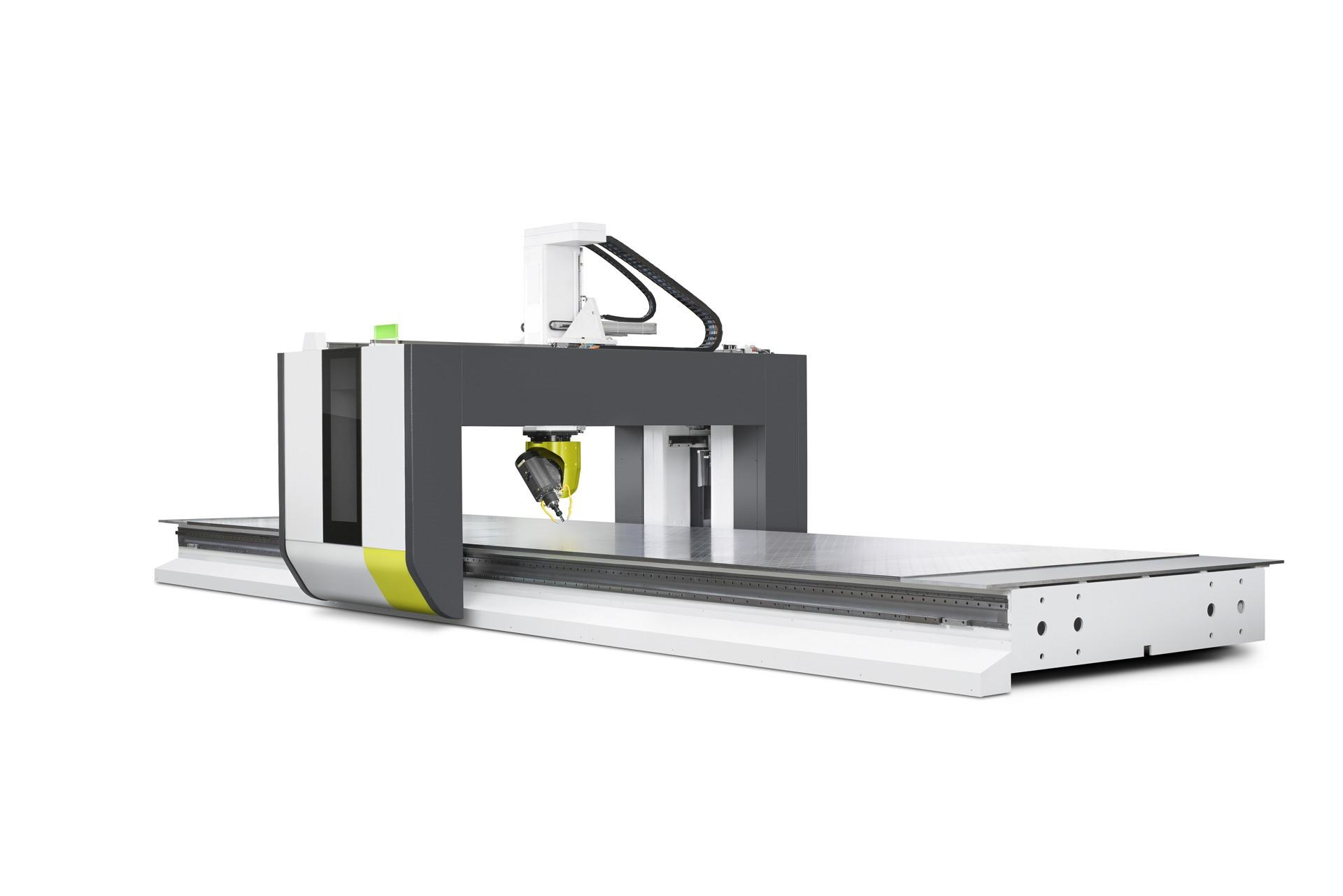

Lately Betech invested in a unique, large and accurate machine. Thanks to the brand new portal milling machine, the 5-axel milling possibilities has increased in both capacity and surface range and a higher accuracy because of the simultaneous operation possibilities.

With its 2.200 mm x 4.000 mm surface range and a maximun heigth of 600 mm, the new machine is a concrete asset to Betech Plastics. Large, complex parts can now be produced within less fixtures, which leads to better quality and reduce of time.

De voordelen

- Increasing efficiency because of 5-axis and simultaneous milling

- Bigger products thanks the 2.200 mm x 4.000 mm x 600 mm surface range

- High stability and accuracy

5-axis simultaneous milling

Because of the possibility to do 5-axel simultaneous milling, multiple axis can be moved at the same time which leads to the creating of complex shapes. Moreover, 5-axis simultaneous milling reduces the cycle time and the amount of fixtures needed to produce a part. Given the fact that there is a expanding ask of plastic parts with tolerances as high as possible, this is a huge added value to the market.

Substantial expansion of surface

Thanks to the surface range of max. 2.200 mm x 4.000 mm x 600 mm, the 5-axis surface has increased substantially. This machine makes it possible to produce a large serie of parts with a 5-axel operation needed, whithout using robots or any other extra operation.

Betech Plastics is specialized in the processing of technical engineering plastics by turning, milling and lasering. In addition glueing, welding, bowing and assembling activities such as application of inserts or helicoils are part of the capabilities.